System Logistics : Shuttle & Palletizing system

Picking solutions

LogiMate

LogiMate Solutions can support a wide range of Picking and Order Fulfillment Activities, from the most advanced automated case-picking applications (MOPS) to the most efficient Unit Picking solutions based on the use of ergonomic GTP stations.

MOPS solutions, empowered by the well-renown System Logistics Best-Fit Software for the creation of perfectly built mixed order pallets, are specifically designed for working natively with an extensive range of FMCG package types, making it the perfect solutions for high volumes order fulfillment centers within the Food, Beverage & Grocery industries.

Type

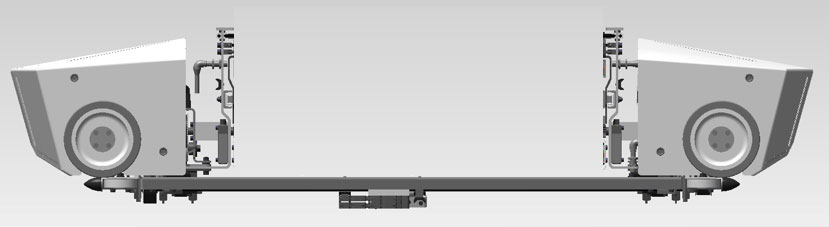

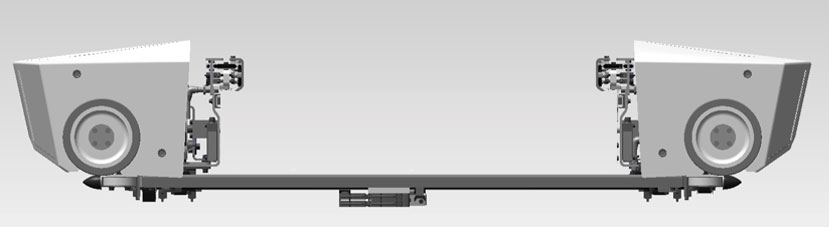

LogiMate "LG" (Loose and deformable Goods)

Specific for Robotized Automatic Picking Systems

Type

LogiMate "CT" (Standard Plastic Totes, Trays and Cartons)

Specific for Goods-to-man picking applications

LOGIMATE TYPES

| Names | LogiMate LG | LogiMate CT |

|---|---|---|

| Main Applications | Grocery/Variable goods sizes | Totes and Cartons applications |

| Min. sizes | 150 x 120 x 30 | 250 x 150 x 50 |

| Max. sizes | Single 920 x 600 x 490 Double 600 x 425 x 490 |

Single 920 x 620 x 490 Double 660 x 425 x 490 |

| H shuttle level-level distance (min.) | 375 mm | 337,5 mm |

| Load Capacity | Single 70 Kg Double 35 + 35 Kg |

Single 100 Kg Double 50 + 50 Kg |

| Speed & Acceleration max. (X) | 4,2 m/s - 1,4 m/s2 | 4,2 m/s - 1,4 m/s2 |

| Speed & Acceleration Full Load (X) | 4 m/s - 1 m/s2 | 3,6 m/s - 0,8 m/s2 |

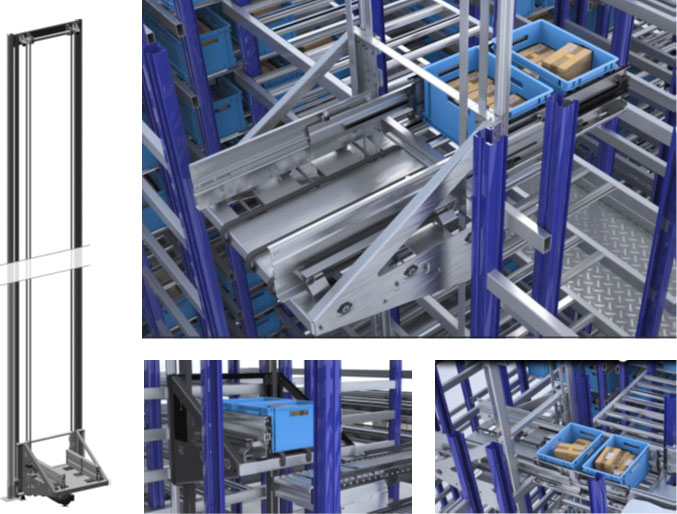

ELCO ELEVATOR FOR CARTONS AND CRATES(LogiMate Elevator for for Cartons, Crates and Loose Goods)

The LogiMate elevator is the interface equipment between shuttle and conveyors.

- Flexible lay-out designs thanks to the possibility of installation at the aisle ends and/or in any other suitable position along the side of the aisle

- Multiple units can operate as a sequencing buffer meeting strict output throughput sequencing needs;

- Direct shuttle handshake interface with no active conveying devices at the levels

- Operates with the same gripping tool used on the LogiMate Shuttle

- High-precision linear bearing lifting system;

- Laser telemeter vertical positioning system;

ELCO SPECSTotes & Goods Lift

ELCO specification

| Max. Payload | Single LU 100 Kg. Double LU 50 + 50 Kg. |

|---|---|

| Vmax without load | 5 m/s |

| Amax without load | 7 m/s2 |

| Vmax with max load | 4 m/s |

| Amax with max load | 4 m/s2 |

| Min. Load Unit | 150 x 120 x 30 mm |

| Max. Load Unit | 920 x 600 x 490 mm |

| Data Transmission | Cable Chain |

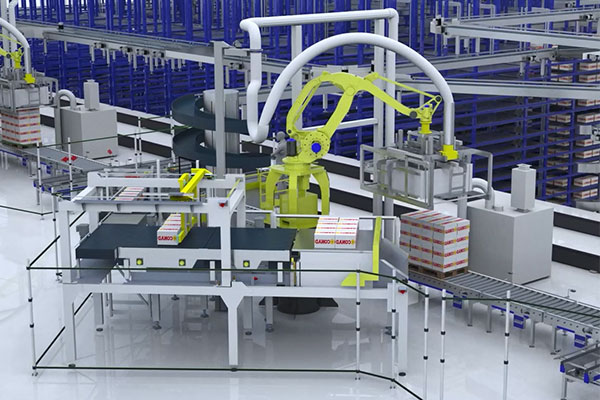

Pick MatePalletizing system

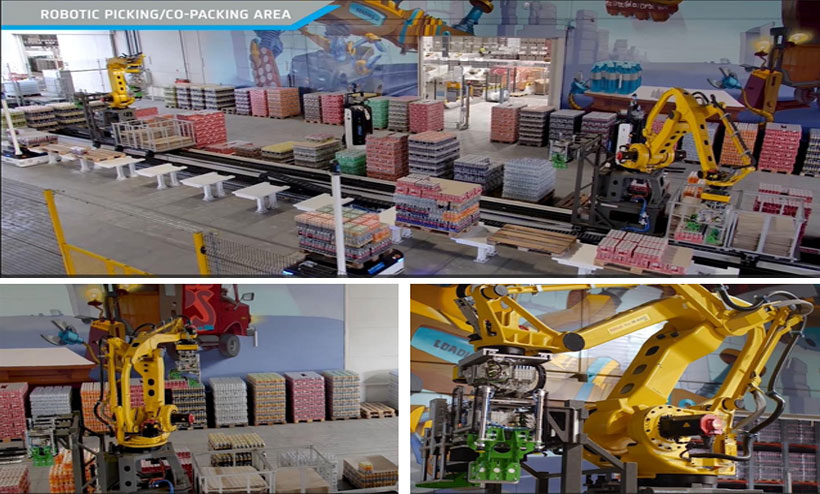

- FANUC 4 axis robot with customized mechanical/vacuum gripper provides great flexibility to handle any types of products, both in shape and size up to 250 kg weight

- Machine cycle time average 30 sec/layer -> 120 layer/h per machine

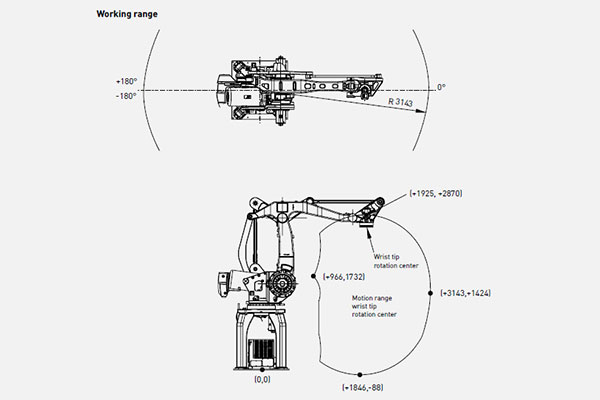

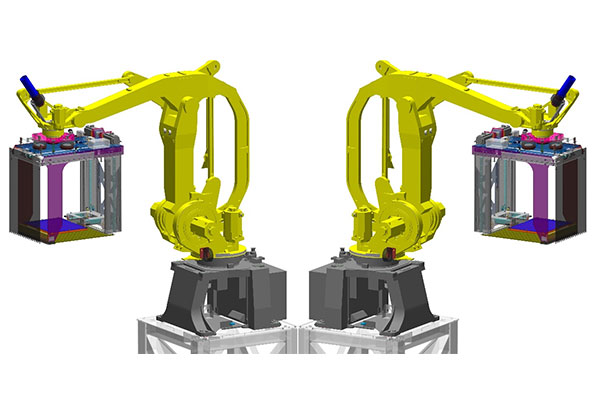

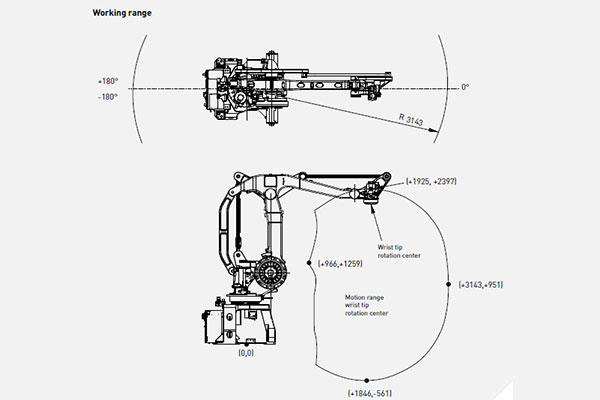

System Logistics – PALLETIZER PALLETIZER - DUAL ROBOT FOR BOX PICKING

- FANUC 4 axis robot with customized mechanical gripper provides great flexibility to handle any types of products, both in shape and size up to 250 kg weight

- Machine cycle time average 4.6 sec/box -> 777 box/h per dual robot

System Logistics – Scope of Supply and Machine Performances

| Summary | ||||

|---|---|---|---|---|

| Machine | Logimate | Box Elevator | De-palletizer | Dual-Robot for box picking |

| Model | SL Shuttle | ELCO | ||

| Velocity x-axis (m/s) | 4.0 | |||

| Acceleration x-axis (m/s2) | 1.0 | |||

| Velocity y-axis (m/s) | 4.0 | |||

| Acceleration y-axis (m/s2) | 4.0 | |||

| LU/h | Avg 120 layer/h | Avg 750 box/h | ||

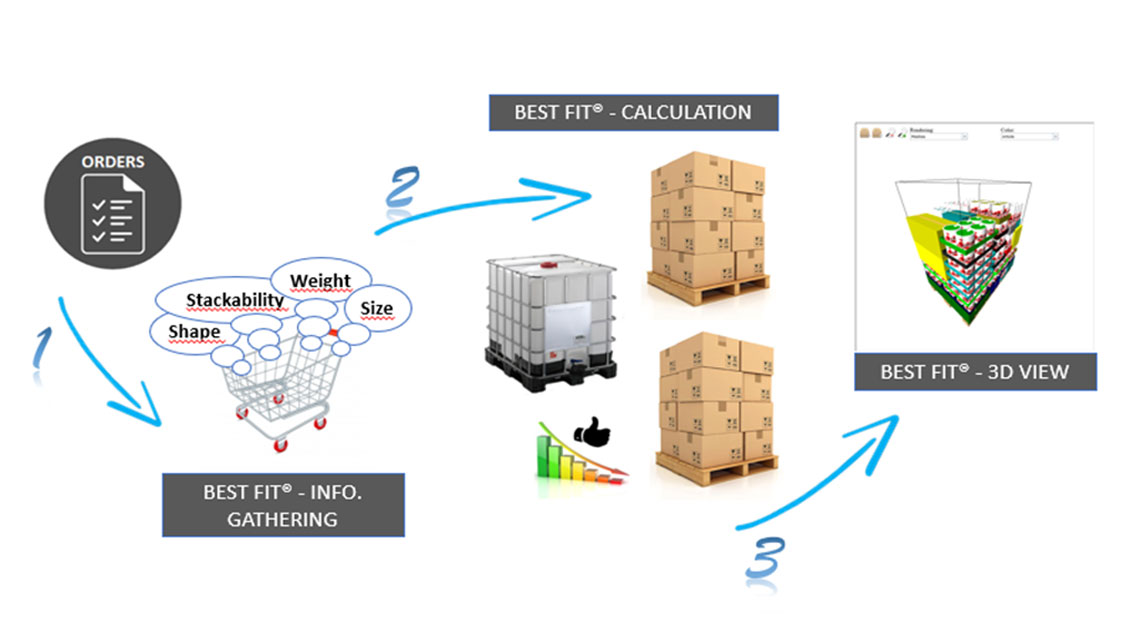

BEST FIT - OVERVIEWSoftware for Best Fitting

- Best Fit is a sophisticated and iterative algorithm for the volumetric calculation

- For each customer order, Best Fit determines the optimum layout and the right sequence for the palletizing, evaluating thousands of variables/parameters simultaneously (Dimensions and weights of packages, Types of packages, type of pallet, etc)

- The Best Fit algorithm takes into consideration the locations of all the full pallets to reduce the movements of the Robot along the linear track and the vehicle stops and paths